Is there a warranty included with the 300B?

Yes. End Users receive a standard ninety (90) day warranty with each tube. If the included warranty card is filled and returned to us by post within ten (10) days of purchase, the warranty is extended to five (5) years.

What is the useful life expectancy of the 300B?

The Western Electric 300B is rated for an average life expectancy of 40,000 hours when operated within published specifications. As far as we know, no replica 300B available today comes close to this life expectancy.

Why are 300B’s engraved with a serial number?

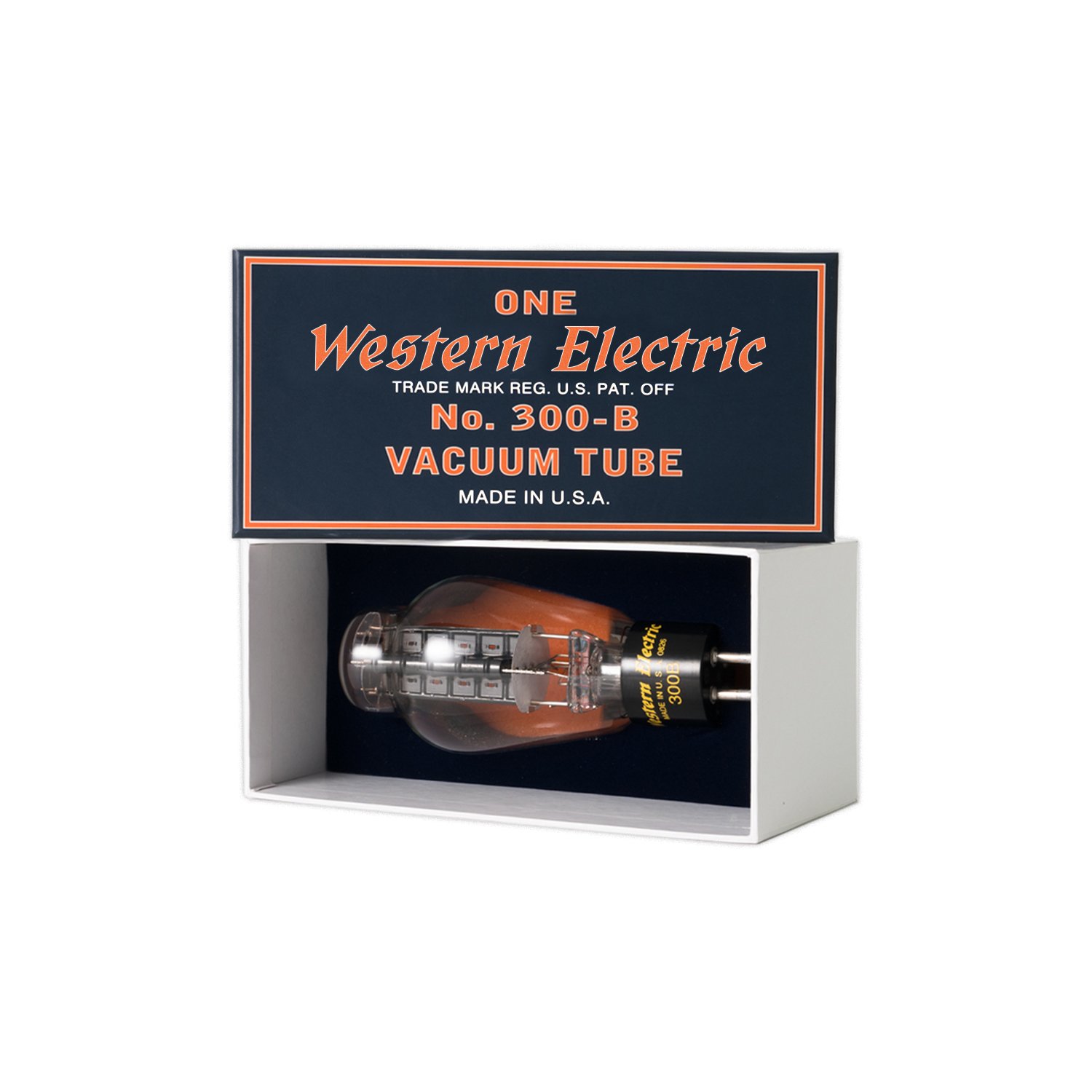

In 1997, we introduced serial number engraving to increase traceability for both the manufacturer and customer and to further avoid counterfeit reproductions. The same number is printed on the carton seal and on a test card that contains test results for each tube. Watch the engraving and base screen printing process here.

How do newly manufactured 300B’s compare to those manufactured in the past?

Western Electric 300B’s have been and always will be manufactured in America following the original 1938 specifications. We rely on historical quality standards, proven manufacturing techniques, and decades of experience to do so. However, in a continuing effort to put quality first we have taken advantage of materials and assembly processes that were not available in the past. For example, current turbomolecular vacuum technology allows us to achieve at least two decades lower (2 x 10-6) Torr than previous runs, resulting in longer tube life. It is also easier than ever to maintain cleanroom practices for increased quality control. Additionally, most of our machinery, like our heat treatment ovens and anode presses, has been computerized for safety and efficiency. We believe our employees and ultimately our customers deserve 21st century manufacturing standards.

Though we do take advantage of modern times, some things remain the same. The 300B’s filamentary cathode core material is derived from a 1963 melt from the Western Electric Hawthorne Works in Chicago. The tooling is also original, some going back as far as 1943.

How are 300B’s matched? Why are matched sets offered?

All pairs and quad sets are computer-matched based on a range of performance characteristics. We capture this data during final inspection and use it during order fulfillment to identify eligible pairs.

Offering tubes that are as close to identical as possible gives the end user confidence. To ensure optimal music playback, end users put great effort into balancing each component that carries the audio signal. A matched set of Western Electric 300B vacuum tubes—when operated within the published specifications with a good amplifier—will never interrupt that “balance.” This is particularly important in push-pull configurations.

What makes the 300B so popular?

The Western Electric 300B is known for its sound quality. The magic is in its directly heated, oxide-coated filament. Though this combination is by no means unique to the 300B, the filament’s coating is. A strontium and barium mix is combined with other proprietary constituents in the filament ribbon to form a coating that was originally developed for use in underwater sea cable applications. We often refer to it as the secret sauce or secret formula. This special coating not only improves the lifetime of each tube, but also supports the dynamics required for superior music reproduction. As a signal is propagated through a 300B, the filament remains “hot,” never fully depleted of electrons and always at the ready. When we experience the pleasurable, water-clear sound of a 300B, we're experiencing the thermal inertia of a directly heated cathode. Learn more about the filament.

I am seeing a blue glow inside my 300B. Does this affect normal operation? Does this effect mean my tube is defective?

A blue glow may appear in the dome of the WE300-B just below the upper mica and the top edge of the plate. The space between the plate and glass is small at this point (less than 1/8”) and appears to be the only area of the tube where this phenomenon takes place. The glow is caused by the electrons striking the plate, volatizing the surface, and dislodging atoms of nickel. High speed barium-strontium electrons from the filament collide with the atom, tearing off electrons, ionizing them and causing a deep blue color even in a well evacuated tube. The resulting glow is a function of the plate voltage and the number of gas molecules in the envelope. In a good vacuum there are still billions of molecules. The electrons travel safely back to the positively charged plate.

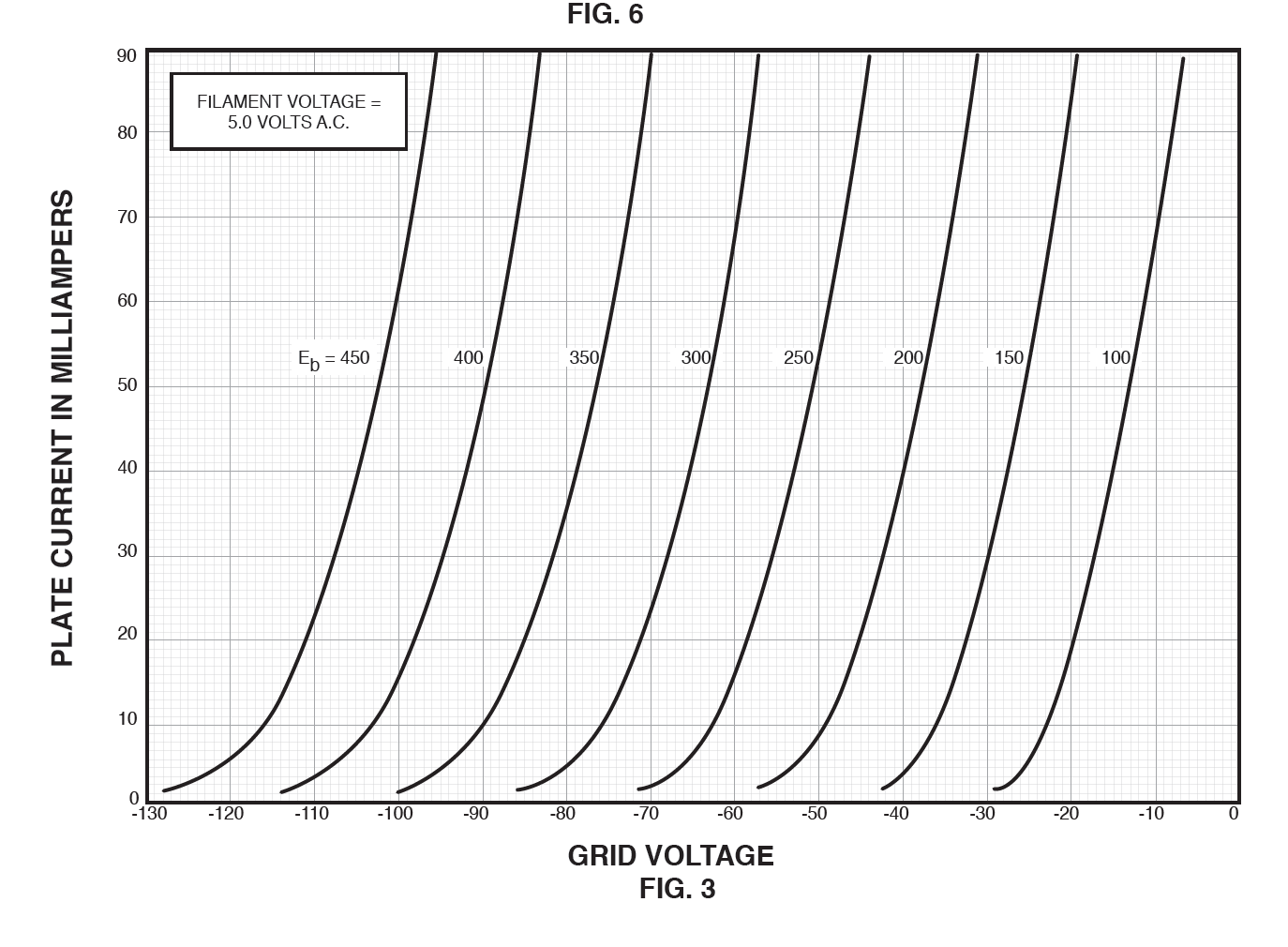

The size of the glow varies with plate voltage and is not the same for each tube and can range from hardly discernible to very obvious, even in daylight. It does not affect tube performance as can be shown by observing the characteristic curves during tube operation.

However, dangerous levels of gas can ionize throughout the entire bulb from a high voltage spark. In this case, the gas will be pink in color and will cause variations in plate current. Air in the tube can ionize in a similar manner throughout the entire bulb, but will appear more blue than pink. In this case, the filament becomes oxidized and emission will drop dramatically.

We ship worldwide

We ship worldwide